New Beams,

Deck & Bulwark

The building of Trim’s entirely new deck

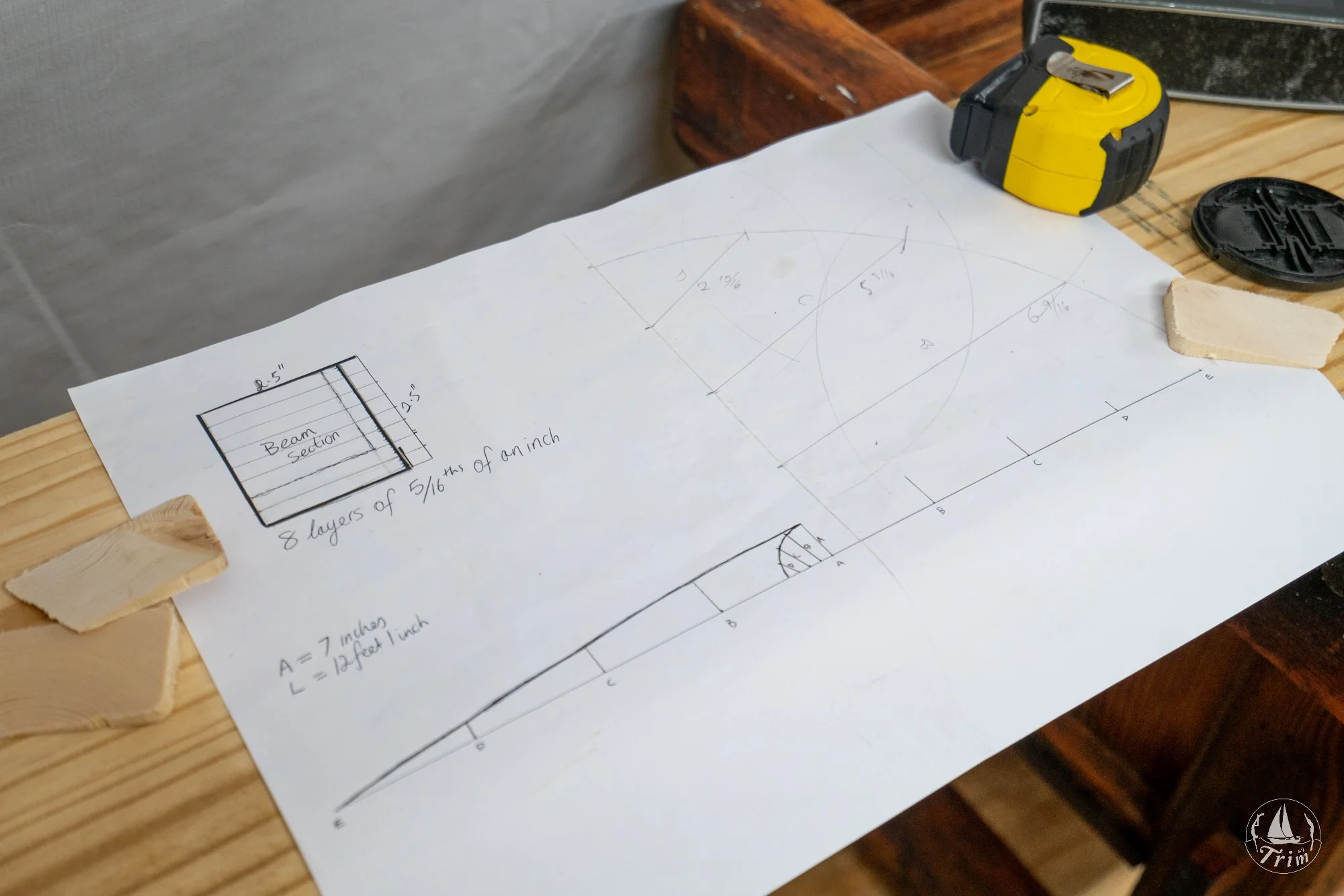

The first step in the process of building a new structural deck was to decide on the construction method and design specifications. I chose to build a fibreglass sheathed, plywood laminated deck fastened to Mahogany beams. Each beam would be laminated with 6 layers of mahogany using epoxy for maximum stiffness and strength for the given dimensions.

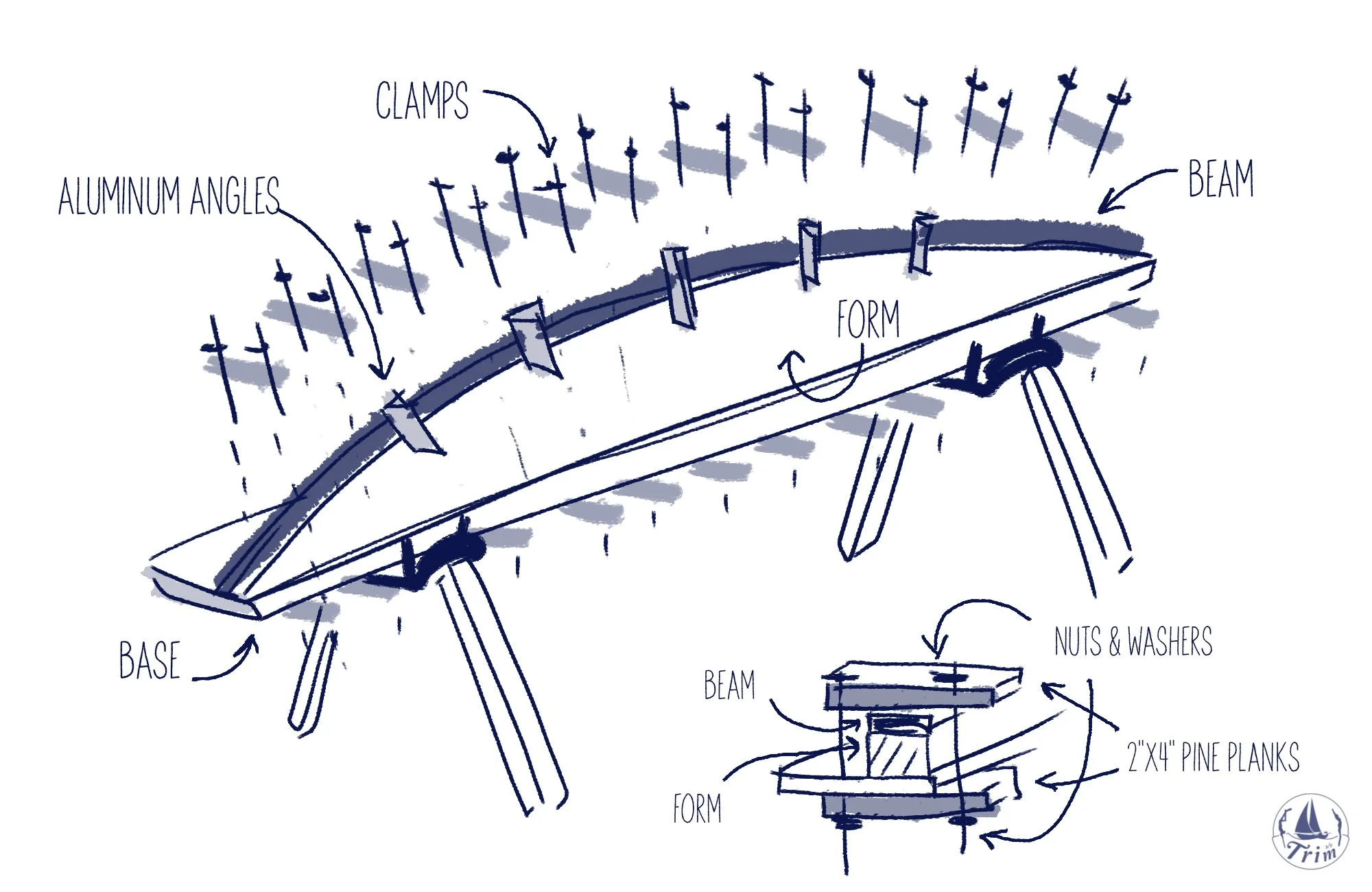

After drafting the desired camber, making allowance for springback, I constructed the form on which the beams would be laminated. I incorporated custom made clamps into the design of the form that would give me good control over clamping pressure. I produced the longest of the deck beams first and as the lengths shortened, increased the camber of the form so as to avoid a flattening effect closer to the bow. Once all 16 beams had been produced, I radiused their outside edges, sanded to 220 and finished them with 8 coats of spar varnish.

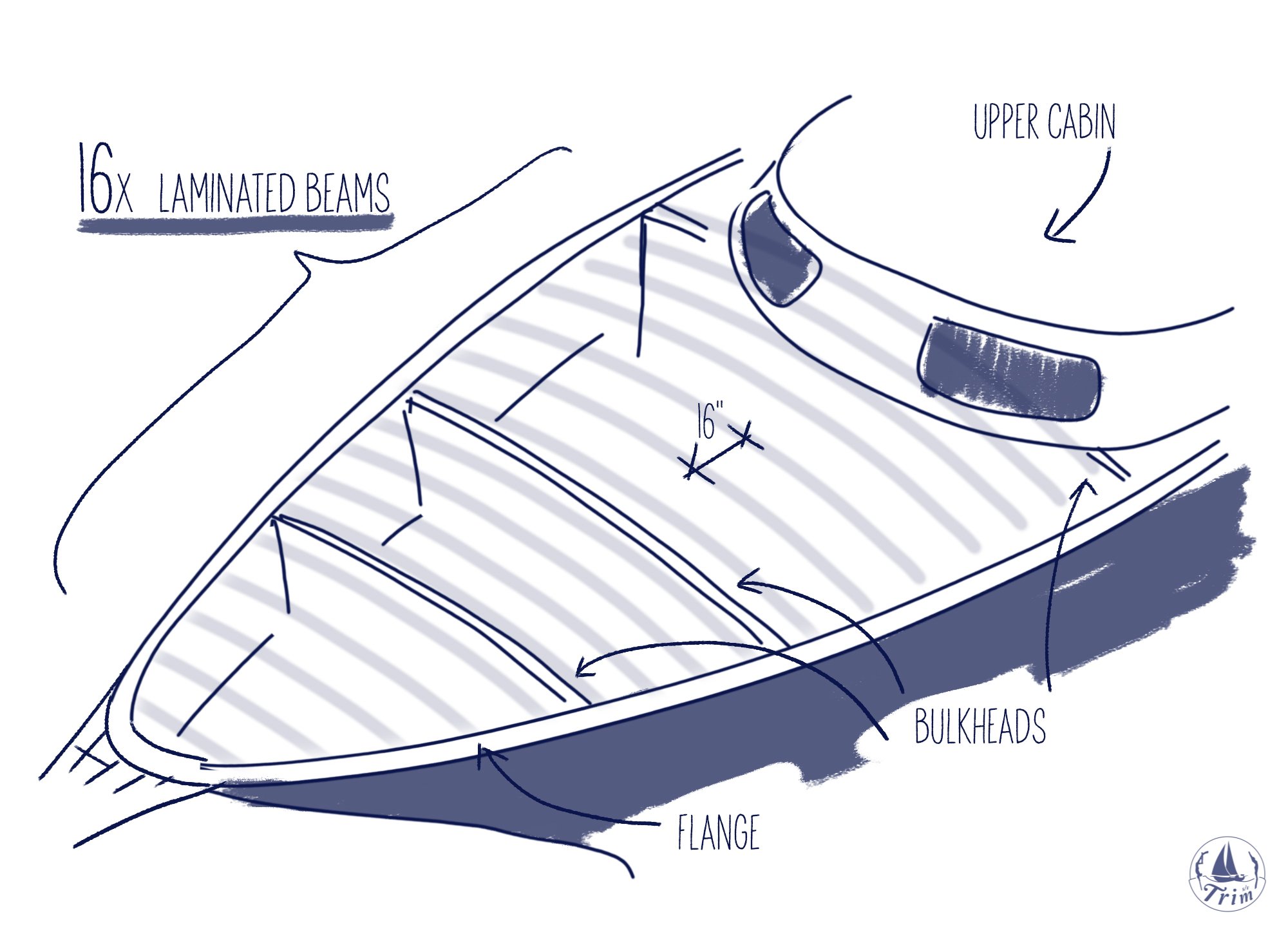

The beams were laid out on 16” (406mm) centres before being glued and through bolted to the fibreglass hull flange. I cut cross halved lap joints down the centreline of each beam to accommodate the king plank which was then glued and fastened in place.

With the deck beams installed, I dry fitted the first layer of 9mm plywood sheathing. This allowed me to mark out the precise location of the beams on the underside of the deck in preparation for paint so as to avoid painting overhead. I rolled and tipped 4 coats of traditional oil enamel on all of the panels, leaving the marked off areas bare to ensure a good bond to the beams. The first layer of 9mm plywood sheathing was then permanently glued and fastened to the deck beams followed by a second 9mm layer bonded with epoxy. The result was a very stiff and strong, structural deck with a thickness of 18mm. I then sheathed the whole deck with a single layer of 10oz fibreglass cloth in epoxy resin to achieve water tightness and abrasion resistance.

A substantial mahogany bulwark was integral to the design of the new deck. The bulwark would tie the deck to the hull in a completely watertight joint, while providing a very strong point of attachment for the stanchion bases. To achieve this, two layers of mahogany in 5 metre lengths were laminated around the curve of the deck, clamped to temporary L brackets. Using two 1” layers benefited the design in two ways. It allowed the timber to be more easily tortured into place around the substantial curve of the bow and it allowed me to utilise a staggered lap joint with large glueing surface area. The bulwark was then glued and through bolted to the deck flange before running an epoxy fillet and fibreglass tape around the entire circumference of the deck to bulwark join.