Engine Rebuild

Restoration of Trim’s “new” engine

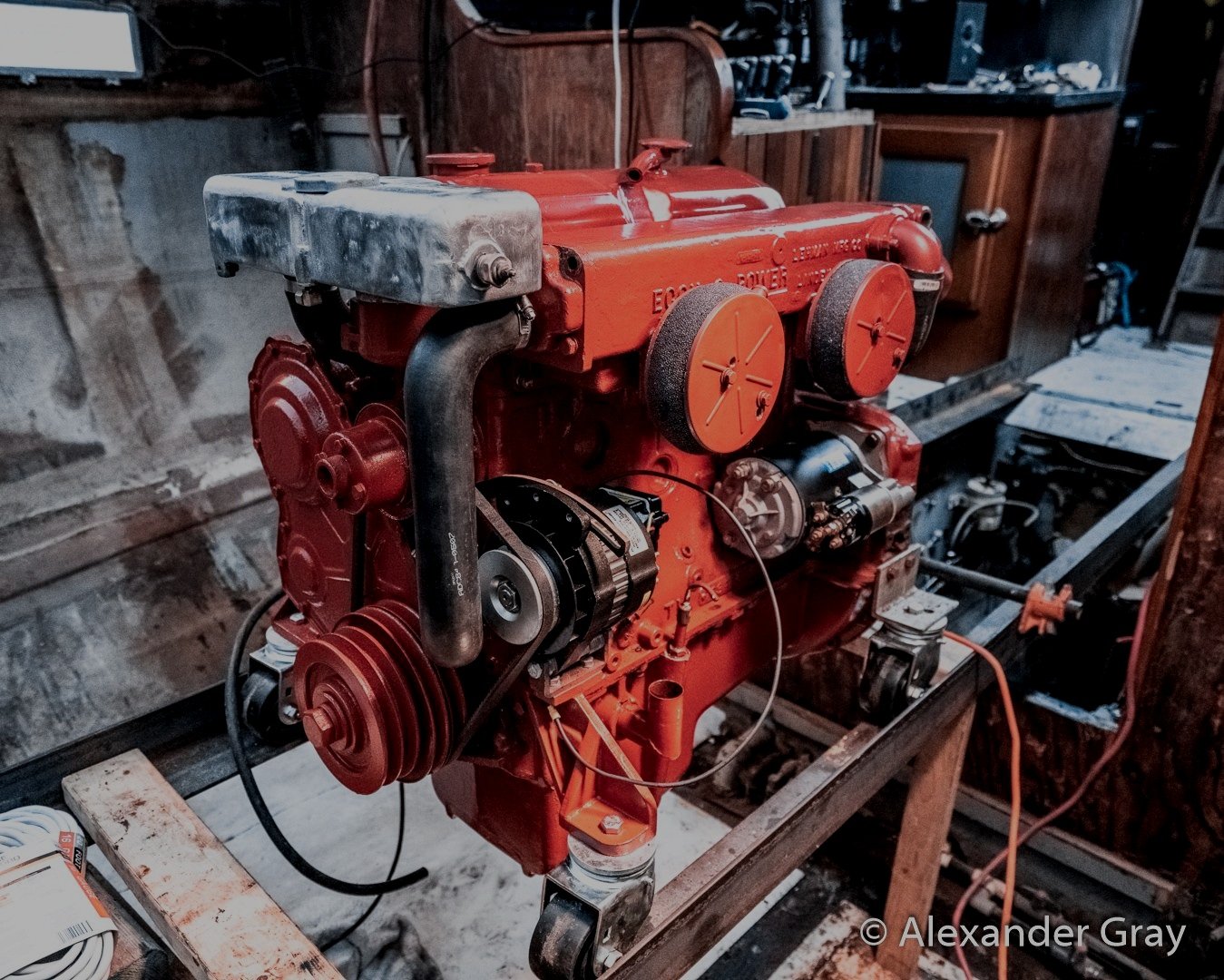

Trim was originally equipped with a Ford Lehman 2712E - a 4 cylinder, naturally aspirated 80hp marine diesel engine. The engine had proved to be a reliable and economical power plant but had been poorly treated over the course of its service life. The exhaust manifold, mixing elbow, coolant tank, heat exchanger, alternator, starter motor, raw water pump and injection pump all needed replacing or servicing.

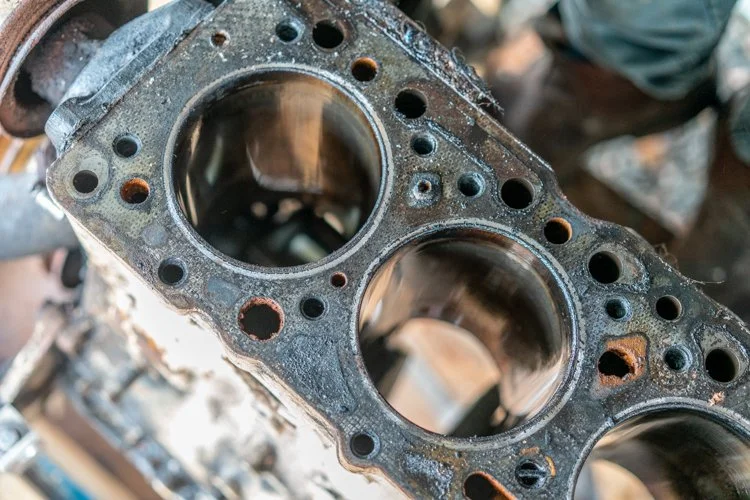

Due to budget constraints, a completely factory rebuilt engine was out of the question but I was able to acquire a used engine of the exact model for a good price locally. This allowed me to source parts I needed to rebuild the engine myself. All peripheral parts were removed from the engine to be evaluated for service or replacement. I removed the head for machining and installed all new gaskets.

The refurbished engine benefited from brand new hoses, clamps, gaskets, starter motor, alternator, raw water pump, fuel lift pump, damper plate, engine mounts, mixing elbow and exhaust system. On re-installation, I learnt how to accurately align the engine with the propeller shaft. The installation was complete upon completing a full rewire of all engine electronics, including gauges, alarms and start/stop solenoid circuits.